EQUIPMENT

CRIMPING TOOLS

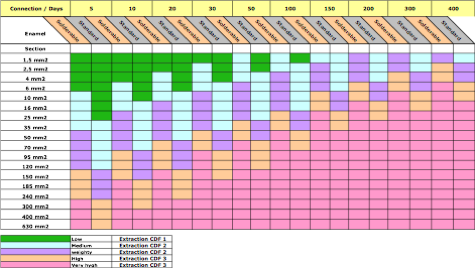

The design of the crimping jaws should consider :

- Composition of your cable

- Copper or aluminium cross section

- Your cable geometry (Round, Rectangular or Square)

- From connector use

Step 1 Set up a connector type

We can help you along this step :

- By directing you to the most appropriate connector, according to the different standards.

- By offering a design specific to your needs pods (see page 18)

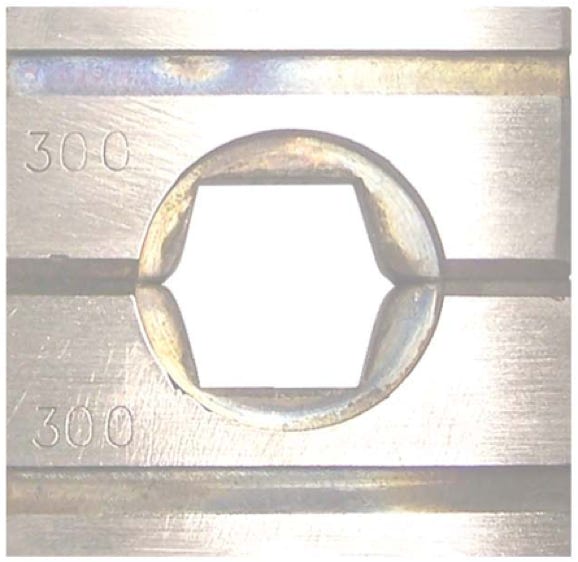

Step 2 Design and material selection

AMR set a specific geometry of the crimping tools thanks to a computer program taking part in the elements mentioned above, to ensure the optimum mechanical and electrical resistance values.

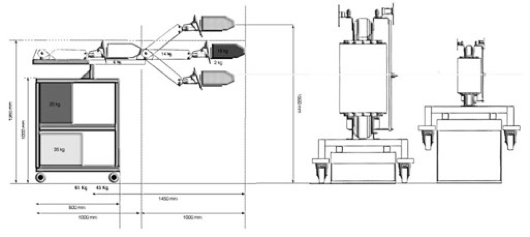

INTEGRATION

AMR achieves the integration according to your specification

- Integration of production line

- Congestion of unit

- Perimeter crimping

- Arm length for deployment

- Mobile or fixed unit

- Smoke extraction system

SMOKE EXTRACTOR